The copper

of the future

of the future

Biocopper® Technology

Using Biocopper® Technology we process sulfide mineral concentrates (Cu, Ni, Zn, Co), in Heap reactors, and electro-refine the charged solutions generated by SX-EW.

Biocopper® Technology:

Clean Refining of Metals

Biocopper® Technology:

Leaching of mineral concentrates.

- Leaching technology for sulfur mineral concentrates in Heap-type reactors, developed and marketed by LIAP.

- It uses a plastic matrix as an agglomeration core, allowing the hydrometallurgical recovery of the contained values.

- Feasibility of using idle Lix-SX-EW plant capabilities.

- Feasible to be applied by various biological and/or chemical oxidizing agents .

- It allows the use of discarded plastics and the re-circularization of plastic waste from mining sites and other industries.

- Triple impact , economic, social, and environmental benefits versus smelters.

Integration of the Primary Mining industry, with secondary processing of own and third-party waste.

Integration with the product life cycle.

- Extension of the useful life of SX-EW plants.

- Application of Biocopper® Technology to process mining waste: fresh tailings and powders, other metals Co, Ni, Zn.

- Integration with secondary products and recycling.

- Reuse of plastic waste (PP, PET, HDPE) from the mining industry (folders, pipes, containers, sacks) and other industries. (Fishing nets, sacks of cement, agro-industry)

- 60T of waste plastic reused in Biocopper® Technology to date.

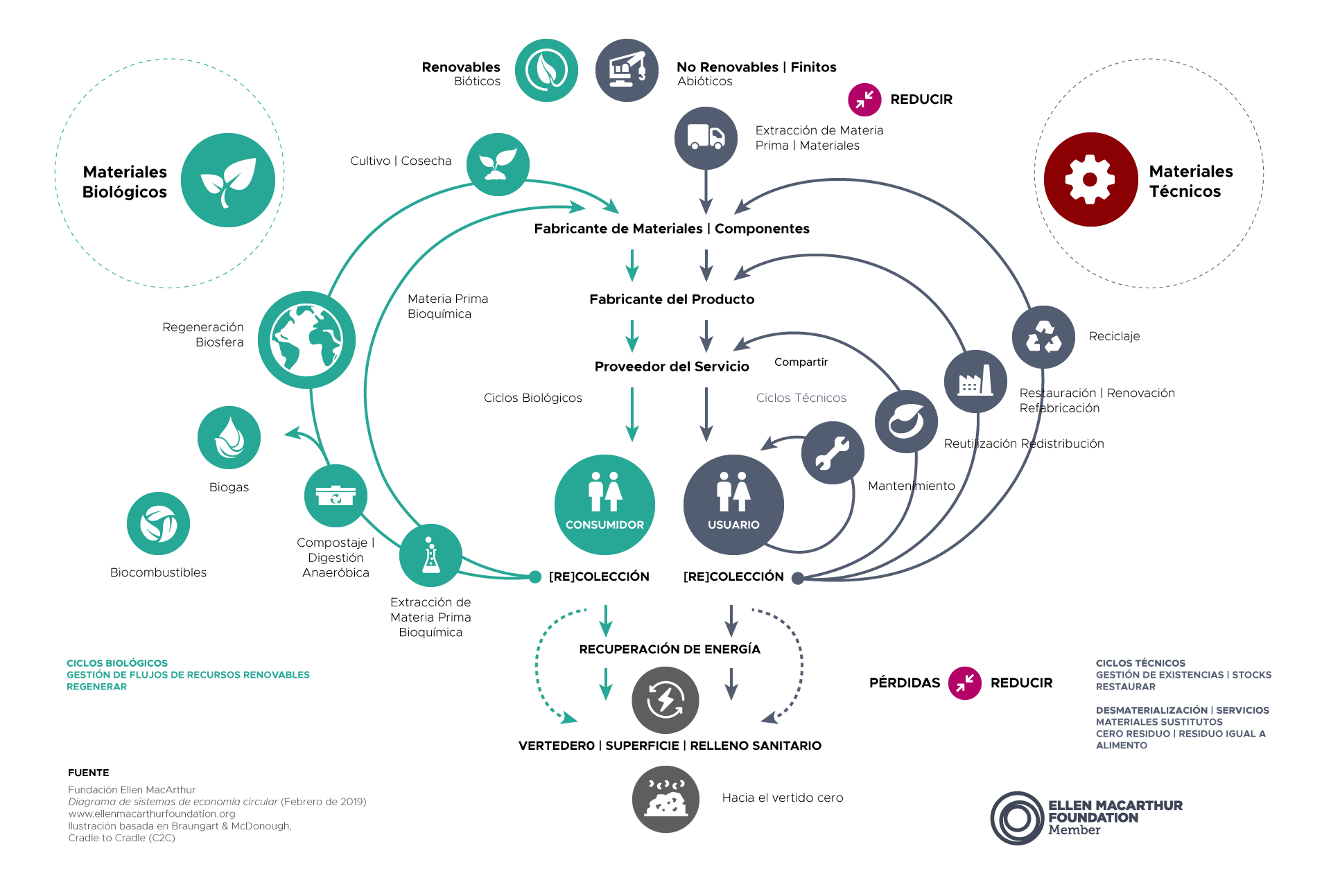

Circular Economy

Regenerative Management Model

Biocopper® Technology presents an opportunity to apply a production model based on Circular Economy from its design.

- Competitive OPEX v/s Smelters US¢20 to US¢30 /TCuf.

- Allows local refining of concentrates in situ.

- Enables complex concentrate processing.

- Enables processing of complex concentrates.

- Clean process, low emissions, based on circular economy.